Last mile logistics are becoming more difficult as consumers become more dependent on online channels for their needs. This article discusses last mile logistics and the advantages of third-party logistics companies. You'll find out how to improve your last mile delivery while maintaining operational excellence. Additionally, you will learn about new technologies and how they can be used to your advantage.

Challenges of last mile logistics

Last-mile logistics can be difficult in rural areas. The distance between urban and rural delivery points can be several miles, and traffic congestion can slow deliveries. E-commerce has made it more important to have faster delivery times and free delivery. In order to meet this demand, logistics companies will need to improve their delivery or fulfillment processes.

Last mile distribution is unpredictable and can lead to long journeys or insufficient transportation. These factors can cause increased costs and time delays. Companies need to have plans for contingencies in case of an unexpected event. For example, if one driver is sick and unable to deliver the product on time, operators must quickly dispatch a replacement driver.

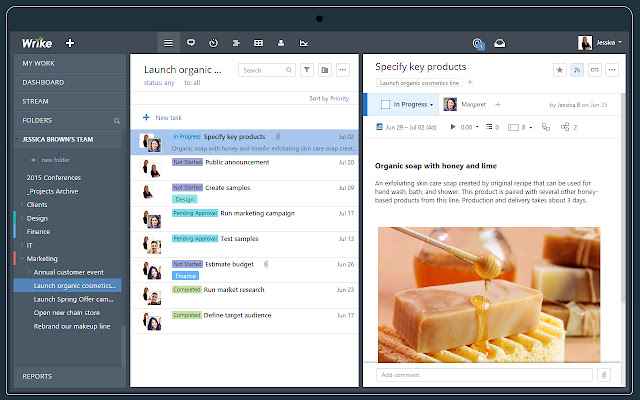

Although last mile logistics can be challenging, there are many technologies that make delivery easier and faster. For example, route optimization technology, which can detect the most cost-efficient routes, will save time and money. Advanced machine learning systems analyze weather patterns, traffic congestion, and road conditions, and will recommend the best routes. Advanced software can help drivers plan their routes and avoid collisions.

Third-party logistics providers offer benefits

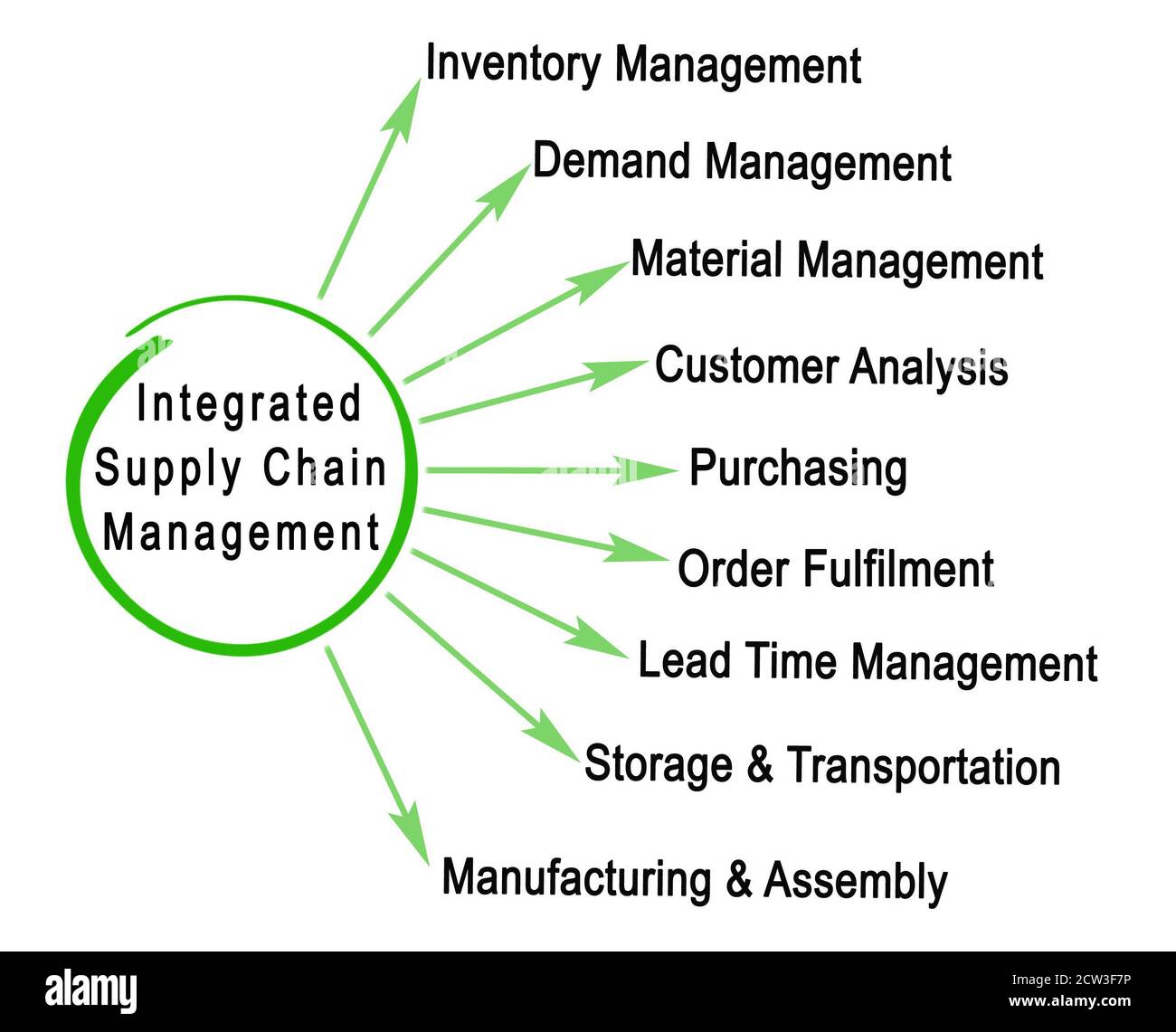

Businesses enjoy a wide range of benefits when third-party logistic providers are involved. They can increase inventory to meet demand, decrease overhead when demand is low and help businesses expand into new markets when it is right. This helps businesses grow and expand into new markets. This allows them to benefit from a more reliable and predictable supply chain that is significantly less expensive than their own logistics.

Outsourcing logistics is a great alternative because it allows the company to focus on its core business. It reduces stress associated with handling non-core logistical tasks. Third-party logistics providers are able to create custom shipping labels and packaging for specific orders. These services have a price, so be prepared to prepare a shipping policy. Shipping mishaps can be covered by this insurance.

Third-party logistics companies also provide warehouse space, inventory control, and logistics technology to eCommerce businesses. For new and expanding eCommerce companies, they can provide quick deliveries. A third-party logistics provider will also take care of stock management and replenish stock when needed. They can also update inventory whenever a customer returns an order.

FAQ

How do you manage your employees effectively?

Achieving employee happiness and productivity is key to managing them effectively.

It means setting clear expectations for them and keeping an eye on their performance.

Managers must be clear about their goals and those of their teams in order to succeed.

They should communicate clearly to staff members. And they need to ensure that they reward good performance and discipline poor performers.

They must also keep records of team activities. These include:

-

What was achieved?

-

How much work were you able to accomplish?

-

Who did it?

-

It was done!

-

Why did it happen?

This data can be used to evaluate and monitor performance.

What is the main difference between Six Sigma Six Sigma TQM and Six Sigma Six Sigma?

The major difference between the two tools for quality management is that six Sigma focuses on eliminating defect while total quality control (TQM), on improving processes and decreasing costs.

Six Sigma stands for continuous improvement. It emphasizes the elimination and improvement of defects using statistical methods, such as control charts, P-charts and Pareto analysis.

This method seeks to decrease variation in product output. This is achieved by identifying and addressing the root causes of problems.

Total quality management involves measuring and monitoring all aspects of the organization. It also includes the training of employees to improve performance.

It is often used to increase productivity.

What is Six Sigma?

This is a method of quality improvement that emphasizes customer service, continuous learning, and customer service. The objective is to eliminate all defects through statistical methods.

Motorola developed Six Sigma in 1986 to help improve its manufacturing processes.

It was quickly adopted by the industry and many companies are now using six-sigma to improve product design, production, delivery, customer service, and product design.

How does a manager learn to manage?

Good management skills are essential for success.

Managers should monitor the performance and progress of their subordinates.

You must act quickly if you notice that your subordinate isn’t performing to their standards.

It is essential to know what areas need to be improved and how to do it.

What are management concepts?

Management Concepts are the management principles and practices that managers use in managing people and resources. They include such topics as human resource policies, job descriptions, performance evaluations, training programs, employee motivation, compensation systems, organizational structure, and many others.

How do you define Six Sigma?

Six-sigma will be well-known to anyone who has worked in operations research or statistics. But anyone can benefit from it.

This requires a lot of dedication, so only people with great leadership skills can make the effort to implement it.

Statistics

- Your choice in Step 5 may very likely be the same or similar to the alternative you placed at the top of your list at the end of Step 4. (umassd.edu)

- 100% of the courses are offered online, and no campus visits are required — a big time-saver for you. (online.uc.edu)

- UpCounsel accepts only the top 5 percent of lawyers on its site. (upcounsel.com)

- The BLS says that financial services jobs like banking are expected to grow 4% by 2030, about as fast as the national average. (wgu.edu)

- Hire the top business lawyers and save up to 60% on legal fees (upcounsel.com)

External Links

How To

How do I get my Six Sigma license?

Six Sigma is a tool for quality management to improve processes and increase efficiency. It is a method that enables companies to achieve consistent results with their operations. The name "Sigmas" comes from the Greek words "sigmas", meaning "six". Motorola created this process in 1986. Motorola recognized the need to standardize manufacturing processes in order to produce better products at a lower cost. The many people involved in manufacturing had caused problems with consistency. To resolve this issue, they used statistical tools like Pareto analysis and control charts. They would then apply these techniques to all aspects of their operation. After applying the technique, they could make improvements wherever there was potential. When you are trying to obtain your Six Sigma certification, there are three steps. To determine whether you are qualified, the first step is to verify your eligibility. Before you can take any tests, you will need to take some classes. You can then start taking the tests once you have completed those classes. You will want to remember everything you learned in the class. You'll then be prepared to take the exam. You'll be certified if your test passes. Finally, you can add your certifications on to your resume.